We are manufacturer of PVC & CPVC granules, full experience on PVC compounding and pipe fitting production.

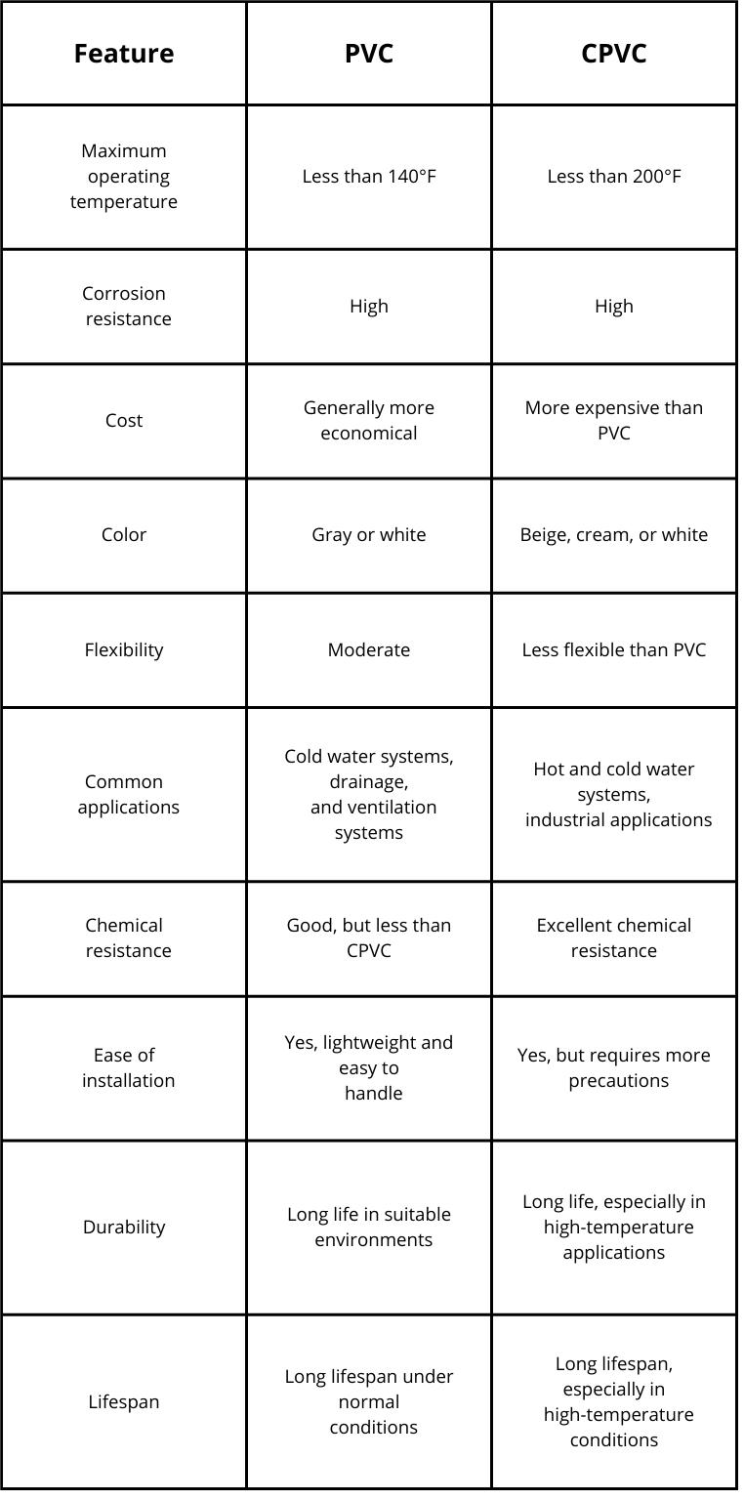

When selecting materials for piping systems, it’s crucial to understand the differences between PVC and CPVC, two popular options due to their versatile properties and applications. Although both share characteristics such as corrosion resistance and ease of installation, each has its own specific features that make it more suitable for certain projects.

In this blog, we will explore the key differences between PVC and CPVC in detail, from their composition and temperature resistance to their common applications and costs, to help you make an informed decision in your next construction or renovation project.

Similarities

Both materials are resistant to corrosion and many chemicals.

Both are lightweight and relatively easy to install.

Both are used in piping systems for transporting liquids.

Both require specific adhesives for joining pipes and fittings.

Differences

CPVC can handle higher temperatures than PVC.

CPVC has greater chemical resistance and is suitable for hot water applications.

The cost of CPVC is typically higher due to its ability to handle higher temperatures and its greater chemical resistance.

CPVC is colored differently, usually to distinguish it from PVC and to indicate its suitability for hot water handling.