Application and industrial future

**Thermoplastic Elastomers (TPEs) and Related Materials: Applications and Industrial Future**

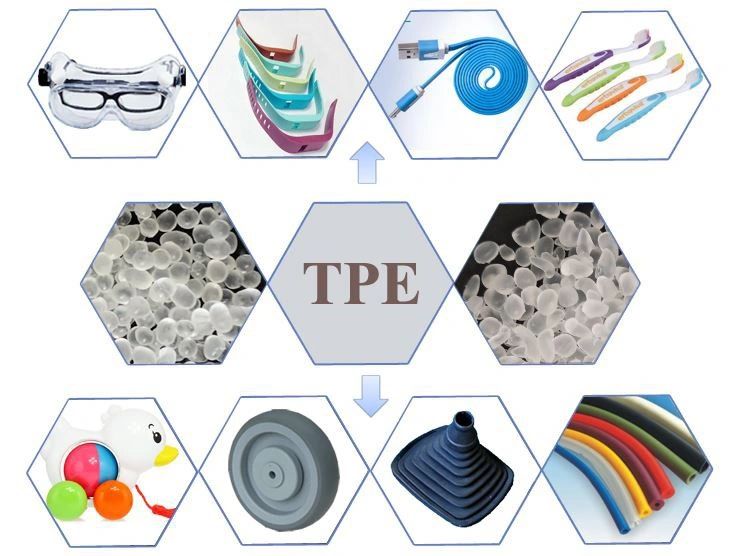

1. **TPE (Thermoplastic Elastomer)**

- **Description**: Combines rubber-like elasticity with thermoplastic processability.

- **Applications**: Consumer goods (phone cases, grips), automotive seals, medical devices (tubing), and footwear.

- **Future**: Growth in recyclable and bio-based formulations, expanding into 3D printing and flexible electronics.

2. **TPR (Thermoplastic Rubber)**

- **Description**: A subset of TPEs with enhanced rubber-like properties.

- **Applications**: Automotive weatherstripping, footwear soles, soft-touch handles.

- **Future**: Increased use in sustainable packaging and lightweight automotive components.

3. **TPU (Thermoplastic Polyurethane)**

- **Description**: Known for high abrasion resistance and elasticity.

- **Applications**: Industrial belts, athletic shoe soles, medical tubing, and protective phone cases.

- **Future**: Growth in wearable technology, automotive interiors, and eco-friendly grades for textiles.

4. **TPV (Thermoplastic Vulcanizate)**

- **Description**: Vulcanized rubber particles in a thermoplastic matrix, offering heat/chemical resistance.

- **Applications**: Automotive under-hood parts (hoses, gaskets), construction seals.

- **Future**: Demand from electric vehicles (EVs) for heat-resistant components and sustainable TPVs.

5. **TPO (Thermoplastic Polyolefin)**

- **Description**: Blend of polyolefins (PP/PE) with elastomers, lightweight and paintable.

- **Applications**: Automotive bumpers, dashboards, roofing membranes.

- **Future**: Expansion in lightweight automotive design and recyclable construction materials.

6. **TPEE (Thermoplastic Polyester Elastomer)**

- **Description**: High strength, fatigue resistance, and temperature stability.

- **Applications**: Industrial hoses, sports equipment, automotive drivetrain components.

- **Future**: Adoption in high-performance EVs, robotics, and energy (solar/wind) applications.

**Industrial Future Trends**:

- **Sustainability**: Bio-based/recyclable grades to meet circular economy goals.

- **Electric Vehicles (EVs)**: Lightweight, durable materials for battery components and interiors.

- **3D Printing**: Flexible filaments for customized medical devices and prototypes.

- **Medical Innovations**: Biocompatible grades for implants and wearable sensors.

- **Advanced Manufacturing**: Enhanced properties (e.g., UV resistance, conductivity) for electronics and renewable energy sectors.

**Challenges**: Cost competition with traditional rubbers, performance limitations in extreme environments, and need for improved recycling infrastructure.

话题标签#plastic 话题标签#polymers 话题标签#TPU 话题标签#TPE 话题标签#TPPE 话题标签#TPR